You hold more computing power in your phone than NASA used to land on the moon. All of that magic lives on something thinner than a fingernail: the microchips. Let’s zoom in — really zoom in — and see why these tiny silicon masterpieces are some of the most beautiful and mind-blowing objects humans have ever created.

1. The Size That Changed Everything

A modern flagship chip (like the Apple A18, Snapdragon 8 Elite or Google Tensor G4) is about the size of your thumbnail, yet it contains 20–30 billion transistors. That’s roughly 3 transistors for every human being on Earth… on one chip.

2. Cities of Light – How a Chip Looks Under the Lens

When you strip away the packaging, a raw silicon die looks like a futuristic metropolis seen from space at night: perfect grids of logic blocks, glowing highways of metal interconnects, and forests of memory cells.

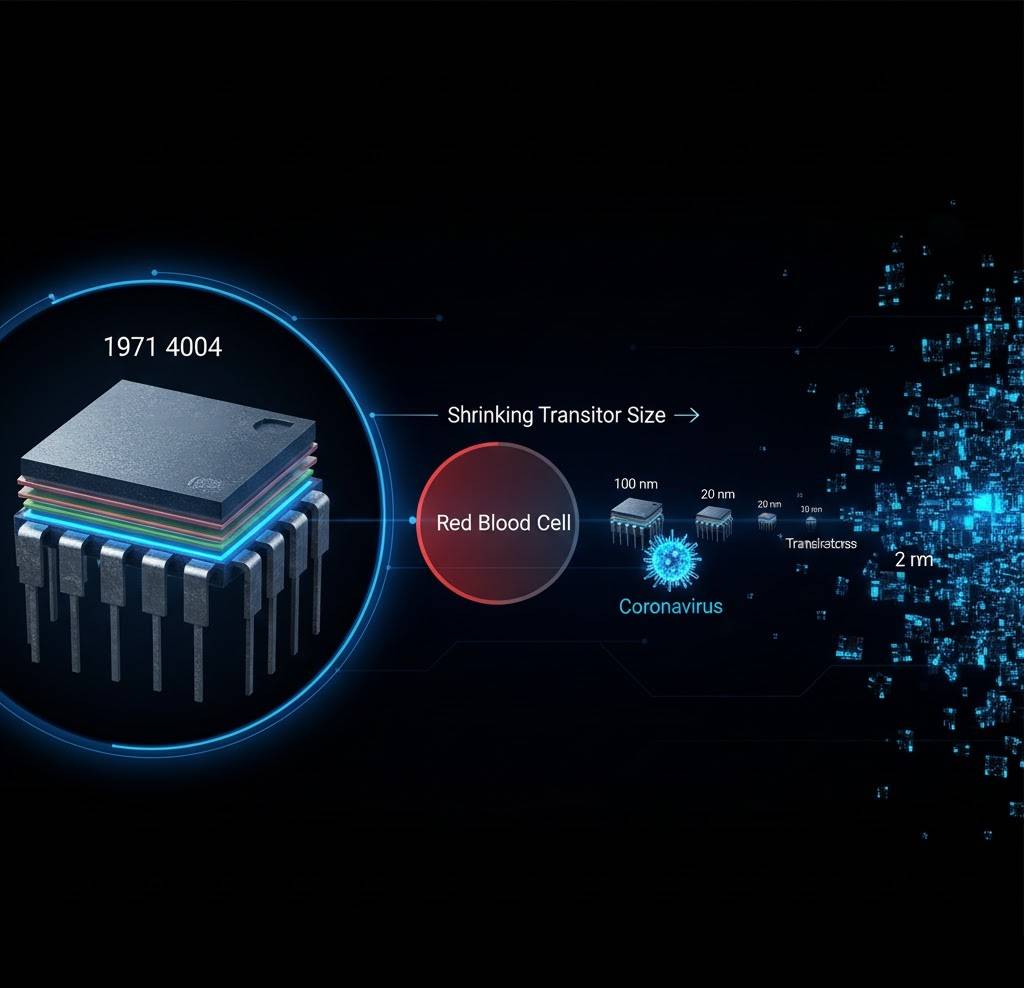

3. The Incredible Shrinking Transistor

In 1971 a transistor was 10,000 nm wide. Today the most advanced nodes (TSMC 2 nm, 2025–2026) are 2 nm — 5,000 times smaller. If a 1971 transistor was the size of a house, today’s is smaller than a virus.

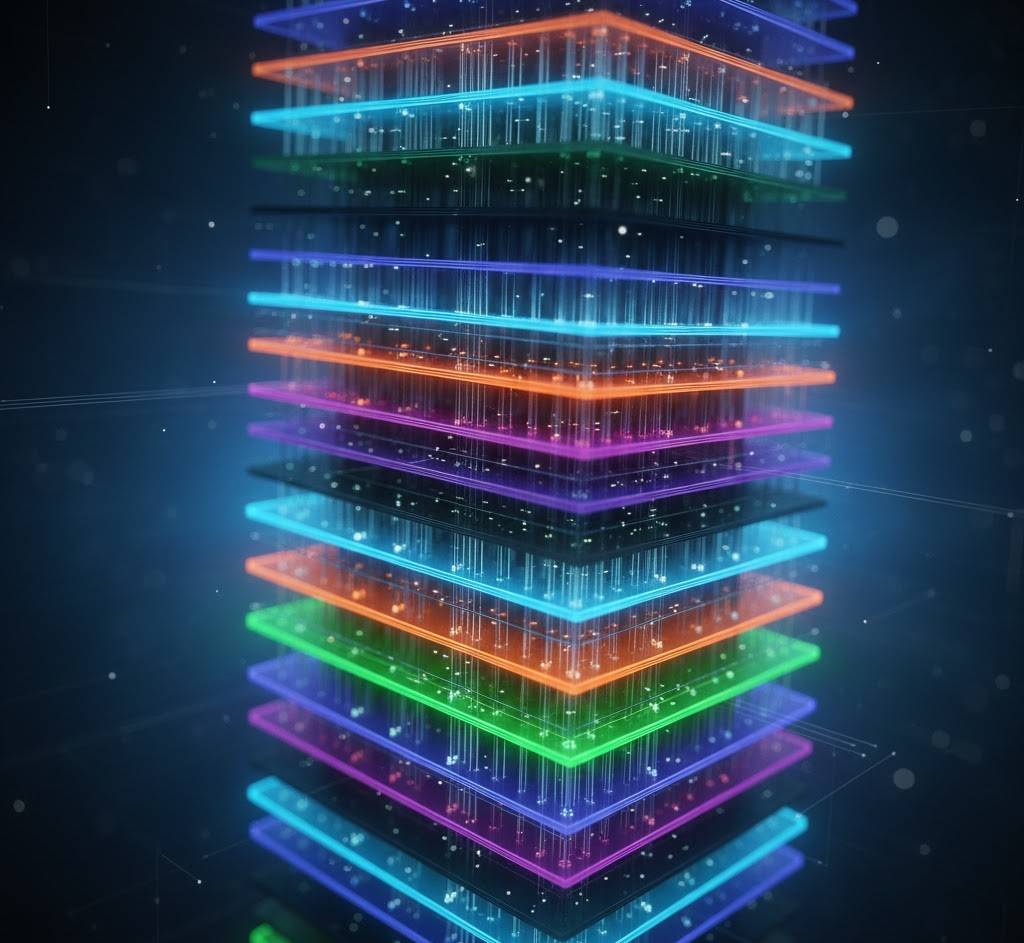

4. Layers Upon Layers – The 3D Architecture

Modern chips aren’t flat anymore. They’re skyscrapers made of 15–20 layers of metal stacked on top of each other with trillions of microscopic vias connecting them, all built atom by atom.

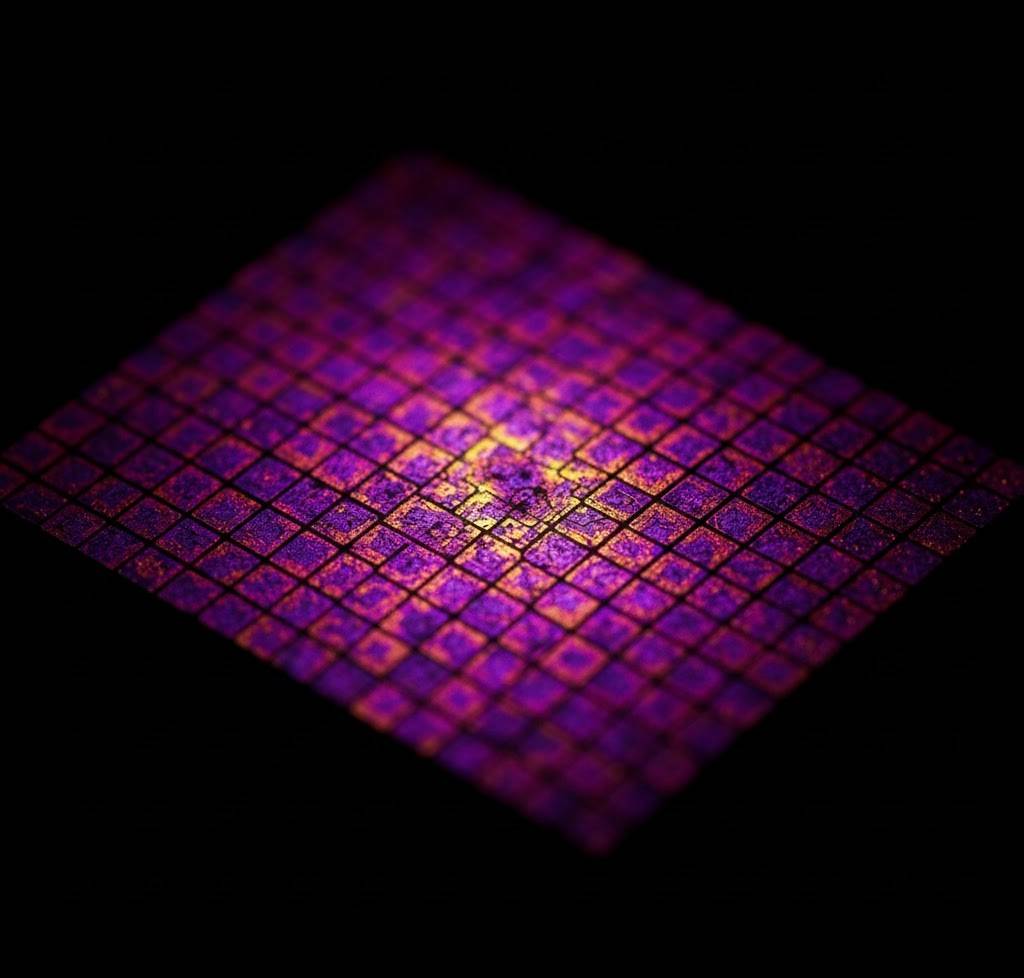

5. The Rainbow Forest – Photolithography Magic

Every pattern on a chip is printed with extreme ultraviolet light (13.5 nm wavelength). The interference patterns create rainbow colors you can see under a microscope — proof that light itself sculpted the chip.

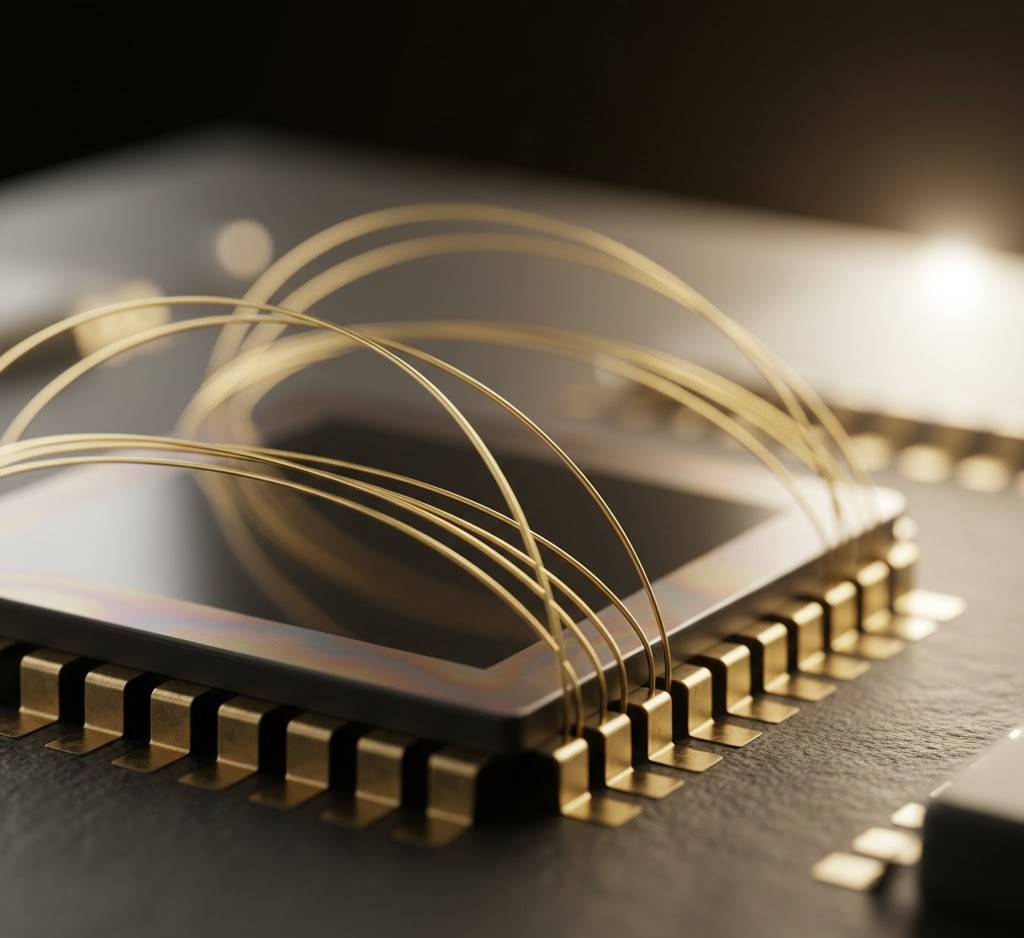

6. Gold Threads Thinner Than Hair

Each chip is connected to its package with gold wires only 20 microns thick — 4× thinner than human hair — bonded with ultrasonic precision.

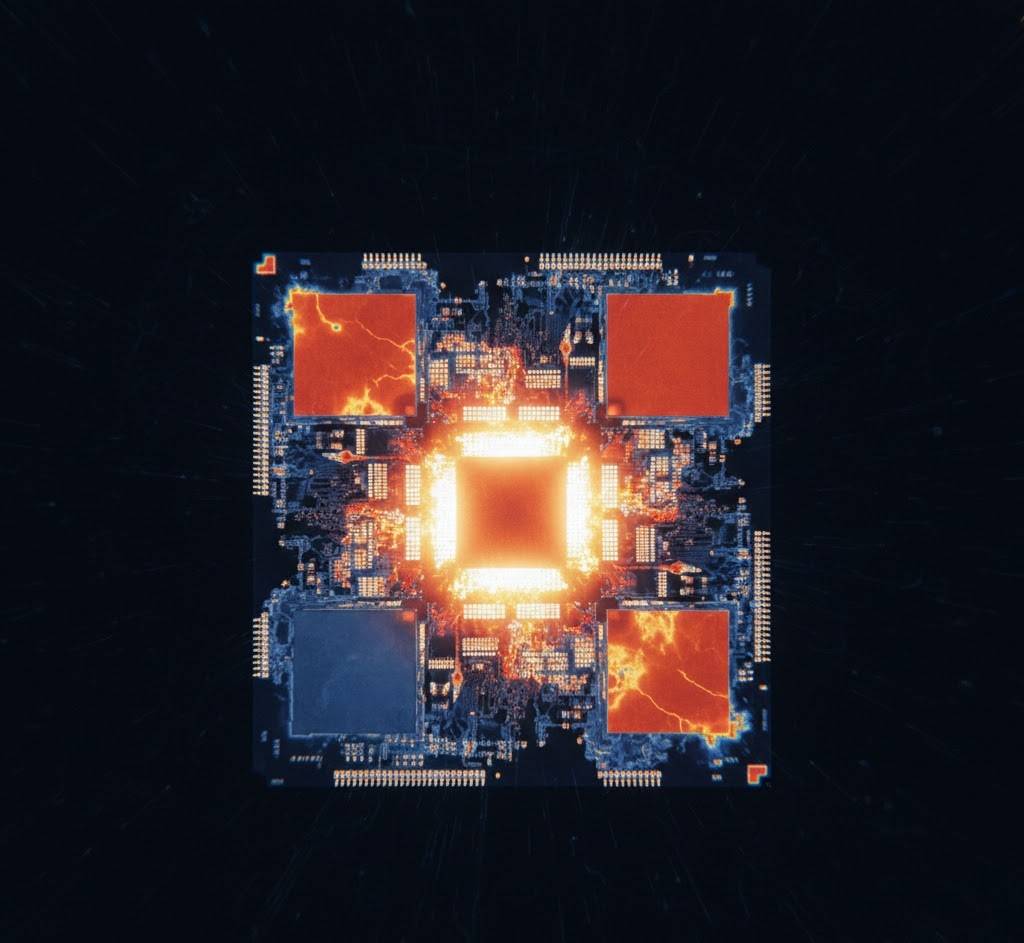

7. The Heat of a Small Sun

When running at full speed, a high-end chip can hit power densities of over 500 W/cm² — hotter per area than the surface of the sun or a nuclear reactor core.

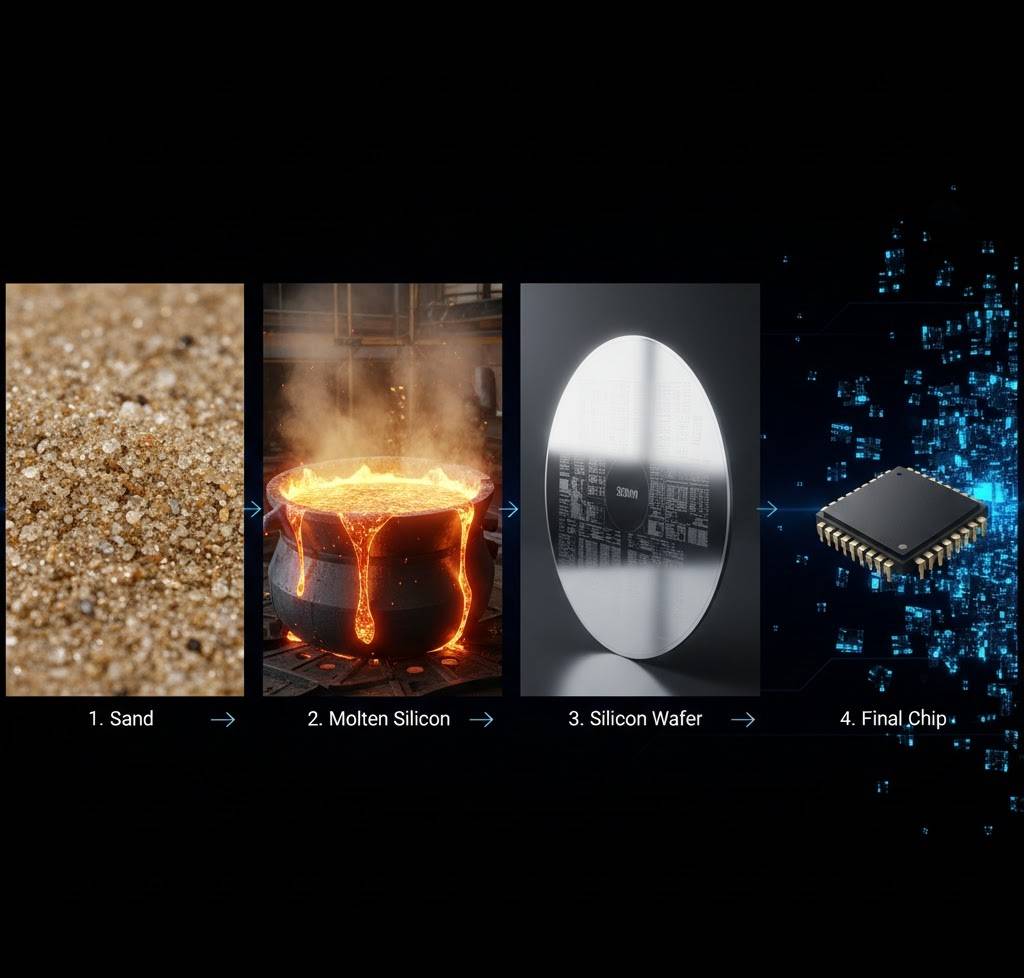

8. From Sand to Sentience

Every chip starts life as beach sand. 99.9999999 % pure silicon is grown into a perfect 300 mm crystal, sliced into wafers, and then carved with light — all in cleanrooms cleaner than operating theaters.

9. The Human Touch (Yes, Really)

Even in 2025–2026, every wafer is still handled by highly trained technicians in “bunny suits.” The most complex object ever mass-produced still needs human care.

Final Thought

Next time you tap your phone screen, remember: you’re touching a piece of near-perfect crystal that contains more engineering than the pyramids, built with 1940s technology. And it cost you less than a good dinner